Project title: An integrated biorefinery for the conversion of dairy side streams to high value bio-based chemicals

Funding programme: Horizon 2020

Action type: BBI Innovation Action (IA) – Flagship

Duration: 01/01/2018 – 31/12/2022

Overview of the AgriChemWhey project

AgriChemWhey will seek to build a first-of-a kind, industrial-scale bio-refinery which will take by-products from the dairy processing industry – excess whey permeate (WP) and delactosed whey permeate (DLP) – and convert them into cost competitive, sustainable lactic acid. This lactic acid can in turn be used to make value-added bio-based products for growing global markets, including biodegradable plastics, bio-based fertiliser and other minerals. This Flagship will prove the techno-economic viability of the innovative WP/DLP-to-lactic acid bio-refinery technology and will provide both the dairy industry and wider society with an opportunity for greater resource efficiency – less food waste, more products from the same starting material (milk), and integration of food and non-food material production.

Project objectives

The overall objective of AgriChemWhey is to build a first-of-a kind industrial-scale biorefinery with integrated symbiotic industrial and agricultural value chains to valorise dairy waste. Specific objectives include:

-

Scale up from Demo-scale (75 MT per capacity annum) to commercial scale (20,000 tonnes per annum capacity) of biorefinery technology for the conversion of food processing residues to food, feed and polymer grade LA and confirming techno-economic viability of the integrated biorefinery approach.

-

Optimise process technologies to reduce the time it takes to produce LA from WP and DLP, increase the yield from 85% to 95% and improve the purification process so that a high purity LA can be achieved using a simplified and energy efficient downstream process.

-

Establish a new WP and DLP to LA and PLA value chain based on increased surplus WP and DLP from the dairy processing industry and create a major new second generation value chain for the growing global LA and PLA market.

-

Establishing industrial symbiosis with local partners to valorise gypsum, calcium phosphate and fermentation residue (bacterial biomass) side streams arising from WP and DLP to LA process for agricultural use and human nutrition to improve sustainability and boosting economic return on investments.

-

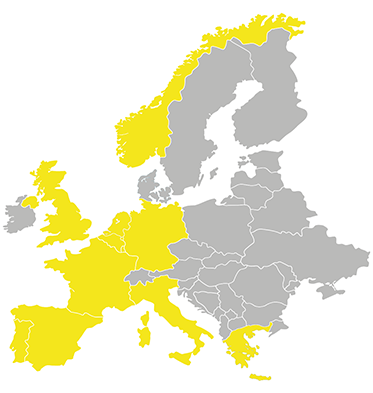

Ensure successful commercial operation of the biorefinery including plans to increase LA production volumes and economies of scale, new capabilities to produce PLA and higher added value valorisation of side-streams and the development of a blueprint for replication of the AgriChemWhey model in other regions across Europe.

Our involvement in the AgriChemWhey project

PNO is involved as key partner for Project Management support, Dissemination and Communication planning and execution, including the management of dissemination materials and stakeholder analysis.